- Vegetable Dehydration Plant

- Vegetable Process Machineries

- French Fries Dryer Plant

- Mushroom Drying Plant

- Paddy / Murmure Dryer Plant

- Fryums 2D 3D Drying Plant

- Extruded Snacks, Fingers & Pellets Drying System

- Short Cut Pasta Production Line

- Makka Poha & Corn Flakes Production Line

- Papad Drying Plant

- Herbal Drying Plant

- Spices Drying System

- Infrared Hot Air Generator

- Material Handling System

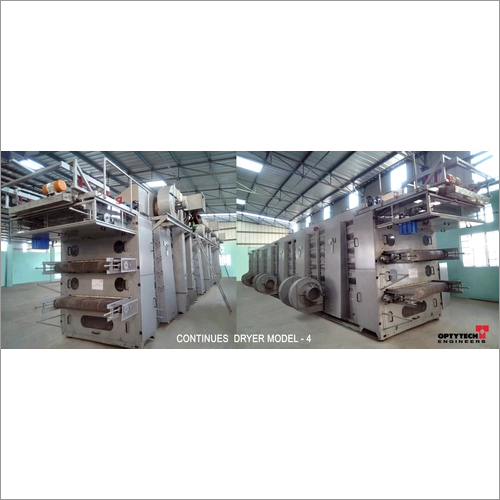

2TPD Vegetable Dehydration Plant

Product Details:

X

Product Description

Enter Buying Requirement Details

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese